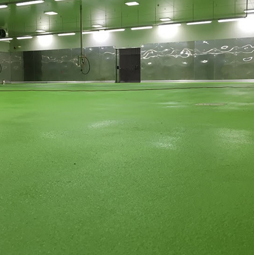

Urethane Cement floors deliver the ultimate in impact and chemical resistance suitable for industrial uses. As the name suggests this type of flooring is comprised of water-based urethane polymers mixed with traditional sand & cement. The resulting surface is significantly harder than concrete, delivering a floor finish that will last 20 years or more.

The self-levelling mixture is applied much more thickly than an Epoxy floor, typically 5-10mm, so the finished floor height may need to be taken into consideration in some areas.

Due to the thicker application and extremely hard finished compound, Urethane Cement is ideal for industrial use, including areas used by heavy plant & machinery. Its is the most impact-resistant of all flooring solutions. It is also the most suitable choice for food preparation areas (eg, fish markets, meat factories, commercial kitchens) and other areas which are regularly exposed to harsh chemicals for cleaning.

Urethane Cement is a breathable coating which allows the transmission of water vapour. For this reason, it is a more suitable solution for areas where the underlying concrete floor is subject to moisture, including low-lying areas near waterways or areas prone to flooding. Using commercial epoxy in such areas could result in the floor delaminating and ‘bubbling up’, whereas this will not happen with Urethane Cement.

The last major consideration when choosing Urethane Cement is speed to install versus factory downtime. Although Urethane cement is more expensive per square meter than Epoxy, because it is self-levelling, it is significantly quicker to install. Together with the fact that in an industrial setting it will likely last 3-times longer, this means that your cost in lost productivity during the lifetime of the floor will be significantly less. We often find this is a clincher for many of our customers, for whom the cost in down time is actually significantly higher than the cost of floor installation.

Perfect for industrial applications subject to high impact & harsh chemicals

Best choice for commercial kitchens, meat factories & food preparation

Thick application & harder than concrete – will last 20+ years

Non-slip surface even when wet

The ultimate in impact-resistant and chemical-resistant flooring

Suitable for areas prone to flooding & slab moisture

Non-slip surface, even when wet

Imagine this: every step you take in your workplace is not just a move forward but a bold statement of how solid and dependable your business really is. Think about it – in a world where making a good first impression is everything and being efficient is the name of the game, can you really afford to skimp on something as crucial as your flooring? That’s where urethane floor coating and urethane flooring come into play.

They’re not just any floors; they’re your business’s way of showing the world that you mean business. Tough, good-looking, and ready for anything, choosing a urethane flooring solution is like giving your workspace a superpower. It’s a simple choice, really. Do you want floors that just look the part, or do you want floors that help you step up your game?

”TEXT”

At Granicrete Australia, we believe that the secret to a thriving workspace lies in the people, processes, and ground they walk on. Our urethane floor coating is not just a layer of protection; it’s a statement of durability, safety, and aesthetic appeal that sets the tone for your business’s ethos.

Dive into the world of urethane concrete flooring, where every granule of sand and polymer is a testament to our commitment to excellence. We guarantee that your flooring is superior to the rest, prepared to bear the demands of industrial strength and commercial beauty, starting with the careful selection of materials and ending with the precise application.

In the quest for the ultimate flooring solution, urethane concrete flooring emerges as the champion for industrial and commercial spaces. But what makes it the preferred choice for businesses across Australia? It’s not just the durability or the aesthetic flexibility; it’s the peace of mind that comes with knowing your floor can handle whatever your business throws at it—literally.

Imagine a floor that laughs in the face of heavy machinery, scoffs at harsh chemicals, and still looks good doing it. That’s the power of urethane flooring. Whether it’s a bustling commercial kitchen or an industrial powerhouse, our flooring stands unyielding, ensuring your operations never skip a beat.

At Granicrete Australia, we understand that ‘one size fits all’ doesn’t apply when it comes to flooring. That’s why we take a bespoke approach, tailoring our urethane concrete flooring solutions to fit the unique contours of your business needs, ensuring that every square inch of your space is optimised for success.

Your business reflects your vision, and your space should be no different. Allow us to bring your concept to life by designing a room that satisfies both your functional and aesthetic requirements. With Granicrete, your floor becomes a canvas that reflects your business’s personality.

Choosing Granicrete is the beginning of a journey toward excellence. Our installation process is designed to be seamless and efficient, minimising downtime and maximising productivity. But our relationship doesn’t end with installation. We’re your partners in success, offering ongoing support to ensure your flooring continues to meet your evolving business needs.

In the long run, our urethane floor coating is not an expense; it’s an investment in durability, safety, and aesthetics that pays dividends in reduced maintenance costs, enhanced operational efficiency, and an elevated brand image. It’s an economic decision that makes sense today and tomorrow.

When you choose Granicrete Australia, you’re not just getting a flooring solution; you’re getting a promise of quality, durability, and customer satisfaction. Our industry-leading guarantees testify to our confidence in our products and our commitment to your success.

Building Relationships, Not Just Floors

At Granicrete, we believe in building lasting relationships with our clients. We’re more than just urethane flooring specialists; we’re your trusted advisors, committed to understanding your needs and exceeding your expectations. By working together, we can lay a foundation that will benefit future generations. Our success is your success.

The future of your business starts from the ground up. With Granicrete Australia’s urethane flooring, you’re not just choosing a floor; you’re choosing a foundation for success—a durable, safe, and aesthetically pleasing foundation. Make the step towards a brighter future with confidence. Choose Granicrete.

Ready to turn your commercial or industrial space into a symbol of success and efficiency? Contact Granicrete Australia now and start your transformation journey. With our urethane floor coating, witness firsthand how the ideal flooring solution can revolutionise your business environment. It’s more than just a change; it’s about creating a future where each step forward is on a foundation as reliable as the goals you’re striving to achieve. Let urethane flooring be the ground upon which your success story is written. Join us, and let’s pave the way to a future where every step is a step on solid, unbeatable ground.

Curiosity didn’t just trouble the cat, it led it to our FAQs! Unleash your inner cat and pounce on the answers you are looking for.

”Close”

Granicrete was very lovely to work with!

I was designing and building a restaurant and Granicrete advised the best flooring to install. Looks great and love the new finish.

Granicrete was very lovely to work with!

I was designing and building a restaurant and Granicrete advised the best flooring to install. Looks great and love the new finish. Knowing whether a Urethane Cement Floor is the right solution for your space, especially compared to other coverings such as Commercial Epoxy can be tricky. It’s a significant investment in both downtime and installation cost, and we do recommend you give us a call to discuss your project before making a final decision. That said, you may find some frequently asked question below helpful.

”TEXT”

Urethane Cement Flooring Melbourne: The Best Flooring Option with Multiple Benefits

Urethane Cement Flooring Melbourne: The Best Flooring Option with Multiple BenefitsEpoxy flooring solution is best known for resurfacing and maintaining the level of existing floors. Urethane cement flooring Melbourne is best regarded as an anti-moisture substance among all flooring solutions. This ability of urethane cement makes it suitable for a number of flooring options for commercial and industrial usage.

Urethane cement, also known as polymer concrete, is made by combining it with a polymer binder, i.e. urethane, along with traditional cement and aggregate. By diluting these substances, we get a smooth and seamless flooring area that is resistant to dampness and microorganisms. As a result, it’s perfect for food processing, pharmaceutical and processing plants.

Urethane cement flooring has a wide range of applications due to its unique properties such as high durability, resistance to moisture, and ability to withstand heavy foot traffic. Here are some of the key applications.

The floors of educational institutions must be water resistant as there could be hundreds of footfall on a daily basis. Choosing a urethane flooring material that can resist moisture is critical to making a durable and anti-slippery floor. The presence of moisture on the floor for some days can lead to bacterial growth, resulting in an outbreak of some diseases. Granicrete Australia recommends using Urethane Cement Flooring for educational institutes as it will increase floor life and make a safe anti-slippery floor.

In automotive plants where manufacturing, assembling and repair work is common, the chances of a damp area are higher. It is because of fluids of certain types at these sites. It is important to take measurements to have damp-proof floors and walls to provide a safe working environment for the workforce and for vehicles as well. Urethane concrete mixture is best for automotive factories as it offers resistance to dampness.

Chemical plants are also prone to catch wetness and dampness, which could be hazardous and even fatal in many cases. This causes serious health and safety hazards, which must be dealt with promptly.

Healthcare centres are the sites where bacteria are present in abundant amounts. To make hospitals and healthcare facilities bacteria-free, the floors and walls should be coated with urethane concrete.

Water is common among food production sites, hotels, restaurants and hospitality centres. For such facilities, it is vital to have a urethane concrete flooring system. This will help for daily cleaning tasks, which involve detergents and the usage of anti-bacterial chemicals of different types. The polyurethane cement will hold the original shape of the floor without fading the colour or shine.

It can also endure a wide range of temperatures due to the way it is constructed, making it an excellent flooring alternative for cold rooms and freezers. It’s also great for industrial plants, warehouses, and chemical factories.

In retail and commercial spaces, aesthetics are as important as durability. Urethane cement flooring can be customized with a variety of colours and finishes to match the decor while providing a durable surface that can withstand high foot traffic.

We provide and install urethane cement flooring Melbourne for commercial and industrial applications. This flooring system has several essential qualities that make it an excellent choice for heavy traffic areas and circumstances where safety is critical.

Using urethane cement for floors comes with many benefits that make it an ideal choice for various commercial and industrial projects. Its ease of maintenance, waterproof nature, and resistance to microbial contamination are just a few of the advantages that make it stand out. Let’s delve into these benefits in more detail.

One of the primary benefits of urethane cement flooring is its ease of cleaning. The smooth, seamless surface of urethane flooring doesn’t trap dirt or dust, making it easy to sweep or mop. This is particularly beneficial in high-traffic areas where dirt and debris can quickly accumulate. Furthermore, urethane flooring is resistant to staining, so spills can be easily wiped up without leaving a mark. This ease of cleaning not only helps maintain the aesthetic appeal of the flooring but also saves time and effort in maintenance.

Urethane cement flooring is non-porous and waterproof, making it an excellent choice for environments where moisture is a concern. Unlike porous flooring materials, urethane doesn’t absorb water or other liquids, preventing the growth of mould and mildew. This waterproof nature also means that urethane flooring is resistant to damage from spills or leaks, making it a durable choice for areas such as kitchens, bathrooms, and industrial settings where liquids are frequently used.

The seamless nature of urethane cement flooring makes it difficult for microbial life, fungus, and other contaminants to take hold. This is a crucial benefit for settings where hygiene is paramount, such as healthcare facilities, food processing plants, and pharmaceutical manufacturing units. The ability to easily sterilize urethane flooring helps maintain a clean, hygienic environment, reducing the risk of contamination and disease transmission.

If you are on the lookout for the best flooring solution for your facility, then urethane cement flooring Melbourne by Granicrete can be the answer. Get a quote today by calling us at, Tel: 03 9467 9111

”Close”